Applied Circuit Services, LLC

Tel: 603-773-2114

Fax: 603-583-4568

............................................................................................................................................................................................................................................

.......................................................

Process Guidelines

Copper via structures are typically formed in one of two ways.

- One method, a complete panel plate, is based on the copper requirements of the copper surface and the via hole. In this method, copper is plated across the entire surface of the panel and into the barrel of the hole.

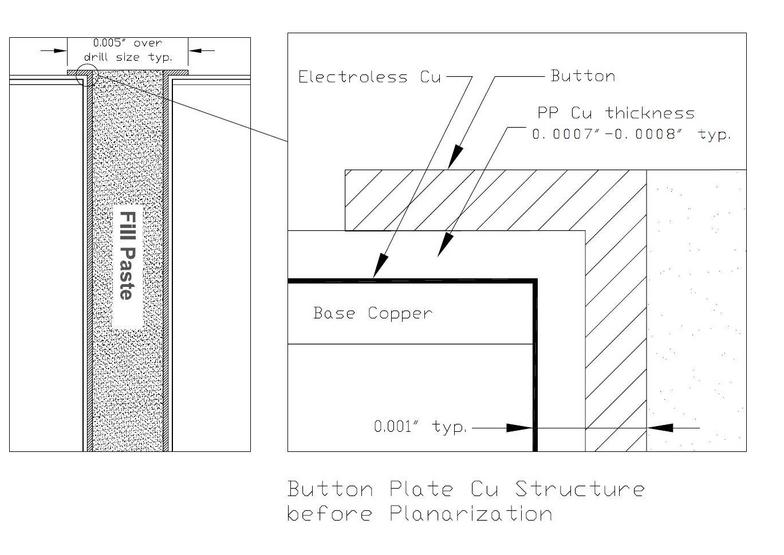

- The second method, button plating, is a combination of panel plating and a pad image over the holes. Typically, the ratio would be 50/50, with 1/2 of the hole wall requirement in panel plating and 1/2 in button plating. This ratio may vary based on IPC wrap requirements and the hole wall thickness requirements of your customer's specifications.

If you have any questions regarding IPC wrap requirements or the above plating methods,

please contact us directly.

Panel Preparation

- All panels must be stripped of dry film resist, precleaned and thoroughly rinsed from all residual plating process chemicals before being sent to us for via fill to avoid potential outgassing.